Our Offering

Our Expertise Includes:

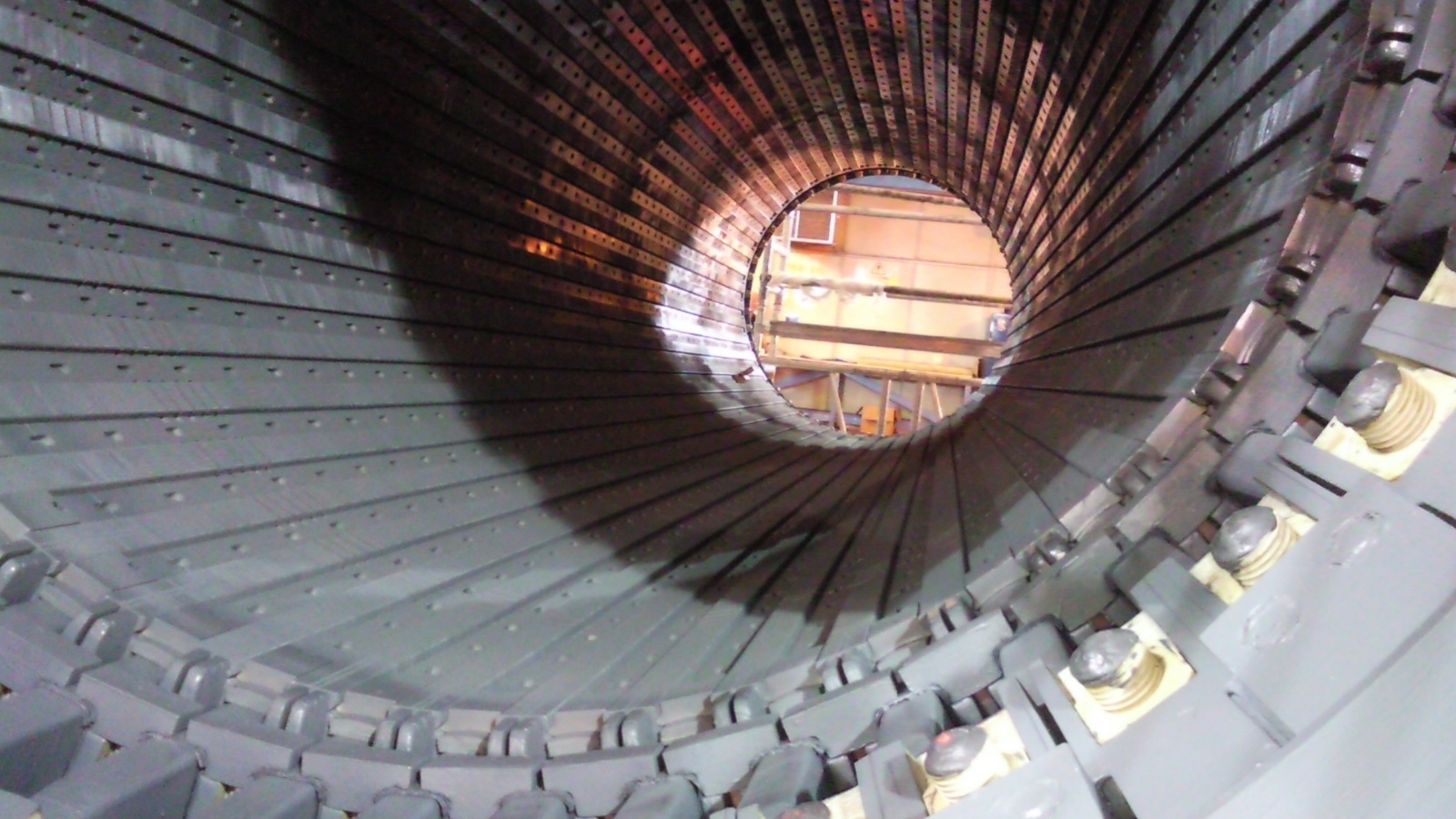

- Full stator rewind

- Partial stator rewind

- End winding tightening and consolidation

- Single bar replacement

- Slot wedge assessment and replacement

- Stator water leak repairs

- Leakage testing of stator winding (for water cooled stators)

- Terminal insulation & bushing replacement

- Stator core local repair by electrolysis method

Generator Rotor Repairs

- Full rotor rewind

- Partial rotor rewind

- Retaining rings removal

- Retaining rings insulation replacement & re-assembly

- Rotor lead replacement

Instrumentation

- Installation of partial discharge sensors

- Installation of rotor flux monitoring systems

- Installation of shaft grounding system

- Installation of stator overhang vibration monitoring sensors

Testing & Diagnosis

- Analysis of Generator test data

- Modal analysis of end winding

- Engineered solutions for the anomalies found in diagnosis

- Rotor RSO and Insulation resistance measurement

- High voltage test

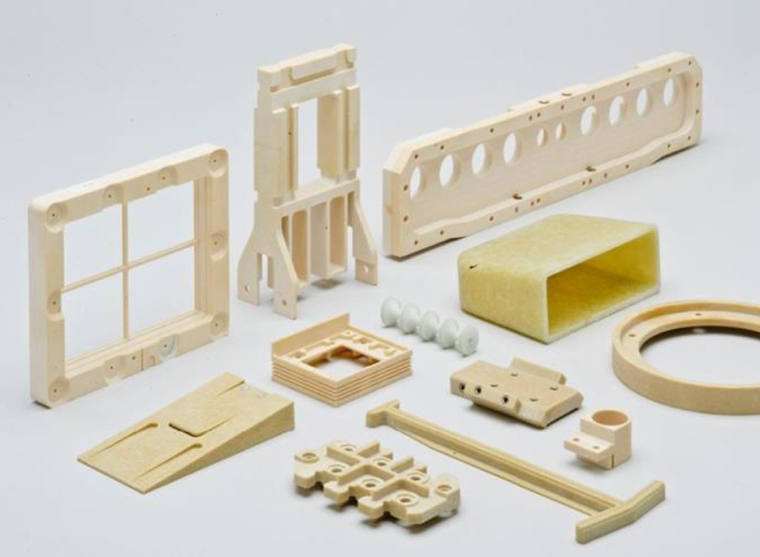

Reverse Engineering & Manufacturing

- Reverse Engineering of all OEM components

- Manufacturing drawing preparation services

- Precision manufacturing of reverse engineered parts

Parts Supply for Stator & Rotor

- Epoxy Slot wedges for stator winding

- Conductive and semi-conductive paints for stator winding

- Concave convex wedging kit for stator

- Lateral slot wedging kit for stator

- Overhang insulation for stator and Rotor winding

- Retaining ring insulation kit

- Resins and Hardeners

- Generator assembly components

- Various types of O rings and gaskets

Let's make something great together.

Get in touch with us for a quick quote